The small desktop 5 axis CNC mill for aluminum is a remarkable innovation in the field of precision machining. This compact yet powerful machine offers numerous advantages for hobbyists, small businesses, and professionals who need to produce intricate parts with high accuracy.

Precision and Flexibility

One of the standout features of a small desktop 5 axis CNC mill for aluminum is its ability to perform complex machining operations with exceptional precision. The five-axis capability allows the machine to move the cutting tool along five different axes simultaneously, enabling the creation of intricate shapes and features that would be challenging or impossible to achieve with traditional three-axis machines. This precision is particularly valuable when working with aluminum, a material commonly used in industries such as aerospace, automotive, and electronics due to its lightweight and durable properties.

Compact and User-Friendly Design

The compact size of a small desktop 5 axis CNC mill makes it an ideal choice for workshops with limited space. Despite its small footprint, this machine does not compromise on performance or capabilities. Its user-friendly interface and intuitive software make it accessible to both experienced machinists and beginners. Many models come with pre-programmed cycles and templates, simplifying the setup process and reducing the learning curve. This ease of use ensures that operators can quickly and efficiently produce high-quality parts without extensive training.

Versatility in Applications

A small desktop 5 axis CNC mill for aluminum is a versatile tool that can be used in a wide range of applications. It is capable of milling, drilling, tapping, and contouring aluminum parts with high precision and efficiency. This versatility makes it suitable for producing everything from prototypes and custom components to small batch production runs. Additionally, the five-axis capability allows for more efficient machining of complex geometries, reducing the need for multiple setups and manual intervention. This not only saves time but also increases overall productivity.

Understanding the Characteristics of Swiss Type CNC Automatic Lathes

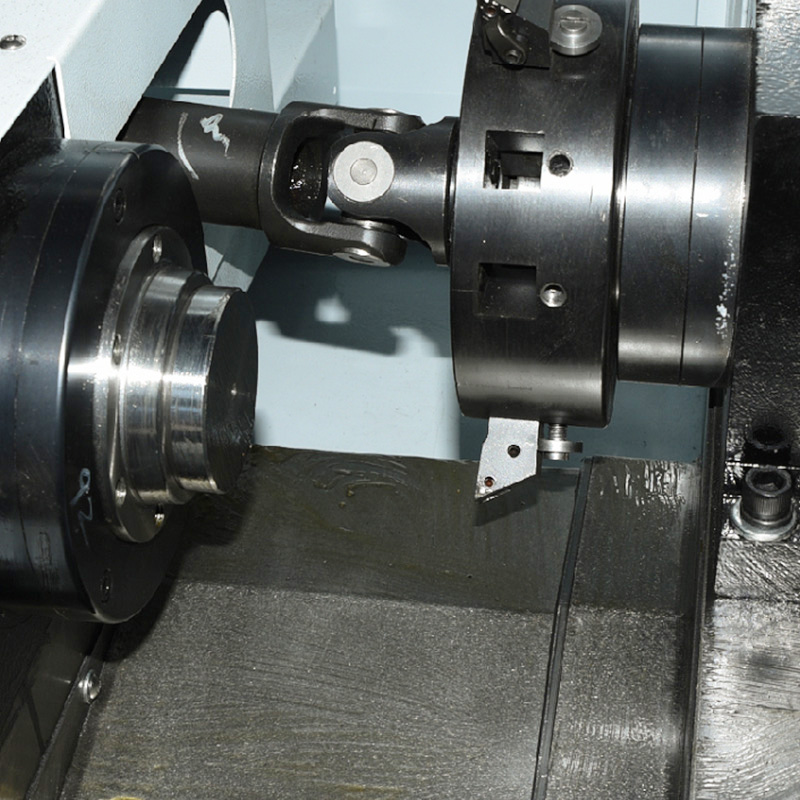

Swiss type CNC automatic lathes are specialized machines designed for precision turning operations. Known for their ability to produce small, complex parts with tight tolerances, these lathes are widely used in industries such as medical device manufacturing, aerospace, and electronics. In this section, we will explore the key characteristics and benefits of Swiss type CNC automatic lathes.

High Precision and Accuracy

Swiss type CNC automatic lathes are renowned for their high precision and accuracy. These machines are designed to hold the workpiece close to the cutting tool, reducing deflection and ensuring consistent dimensional accuracy. This precision is critical when producing parts with tight tolerances and intricate features, such as medical implants, electronic connectors, and aerospace components. The ability to maintain such high levels of accuracy makes Swiss type lathes indispensable for industries that demand exceptional quality and reliability.

Capability for Small and Complex Parts

One of the defining characteristics of Swiss type CNC automatic lathes is their ability to handle small and complex parts. The unique design of these lathes allows for simultaneous machining of multiple features, such as turning, drilling, and milling, in a single setup. This capability is particularly advantageous when producing parts with intricate geometries and multiple features, as it reduces the need for secondary operations and manual intervention. Additionally, Swiss type lathes are equipped with multiple tool stations and live tooling, further enhancing their versatility and efficiency.

Efficient and Continuous Production

Swiss type CNC automatic lathes are designed for efficient and continuous production. The machines are equipped with bar feeders that allow for the automatic feeding of raw material, enabling long, unattended operation. This automation reduces downtime and increases overall productivity, making Swiss type lathes ideal for high-volume production environments. Furthermore, the machines are capable of maintaining tight tolerances over extended periods of operation, ensuring consistent quality and the need for frequent adjustments.

Advanced Control Systems

Modern Swiss type CNC automatic lathes are equipped with advanced control systems that enhance their performance and ease of use. These control systems provide precise control over the machining process, allowing operators to program complex operations with ease. Many systems also include features such as real-time monitoring, diagnostic tools, and automated tool changers, further increasing the efficiency and reliability of the machines. The advanced control systems also contribute to reducing the learning curve, making Swiss type lathes accessible to operators with varying levels of experience.

English

English